Made in the USA

All operations in Chestertown, MD

Leading Provider

of Dip Molded and Coated Products

Certified

ISO9001:2015

Molding and Coating Since 1989

Our dip molding company provides high-quality plastisol components worldwide. Dip molding offers a variety of advantages which may be the perfect fit for your component needs.

Soft Plastic Components

Tight Internal Tolerances

Rapid Product Prototyping

Affordable and Scalable

OUR SERVICES

Our company provides first-class plastisol molding services for organizations worldwide. We utilize dip molding, dip coating, and casting to make a wide range of plastisol products.

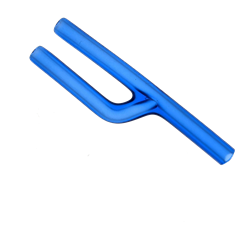

Dip Molding

Connectors, caps, and sleeves

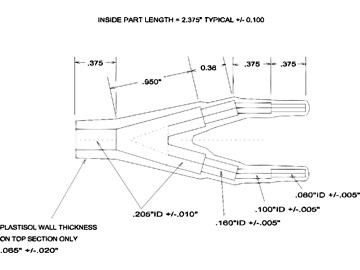

Plastisol dip molding is accomplished by dipping a metal form in a plastisol compound for a controlled length of time, baking it to achieve a thorough cure or fusion, then cooling the part until it is strong enough to be removed from the form without tearing. Though the process sounds simple, the challenge lies in proper development of the forms and establishing optimal parameters to get an acceptable product every time.

Dip Coating

Protective and aesthetic coatings

The dip coating process is very similar to the dip molding process except that no release agent is required and the part being coated becomes the form. Plastisol generally does not adhere well to metal and often requires that the surface be physically or chemically primed. This priming step ensures an appropriate, uniform adhesion.

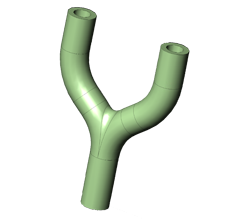

Plastisol Casting

Solid plastisol components

The same techniques used in dip molding and dip coating can be utilized to cast solid objects made of plastisol. Sharing similarities with injection molding, liquid plastisol is poured into a metal mold and heated to cure. The process is highly customizable including cutting out shapes and adding adhesive backings to create adhesive markers.

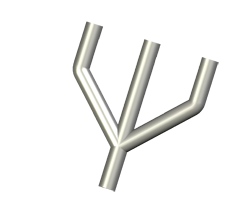

Modeling Services

Industry standard 2D drawings and 3D models

Production sciences utilizes SolidWorks software to turn your concept into a reality. We can take your specifications and create 2D drawings and 3D models. Alternately, we can use your drawings or models as the first step in our prototyping process. Starting with drawings allows us to rapidly develop the molds for your component.

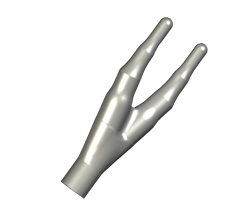

Rapid Prototyping

Concept to sample in as little as one week

Maintaining a machine shop onsite allows us to progress from model to prototype within just a few days, depending on complexity. This capability enables us to make one mold and adjust it as necessary to obtain the optimal configuration. Building and assembling our tooling in this way also allows us to plan and price scaling up for a full production run based on your estimated needs.

Plastisol Selection

Transparent, colored, and additives

Now offering Phthalate-Free options!

Choose from a wide selection of materials from transparent medical-grade to opaque colored for industrial applications. We have experience working with additives such as scents and even compounds to make components radiopaque.